Judging from the situation in the past two years, almost every year there are hot products that drive the popularity of a certain process, such as the two-color injection molding that became popular last year and the skin lamination that attracted much attention this year.

Although “Internet celebrity” processes often represent the cutting-edge fashion trends in the industry, for prudent procurement projects, the adoption of new processes is not an overnight process. Some common processes will continue to be used until the new processes are mature and introduced.

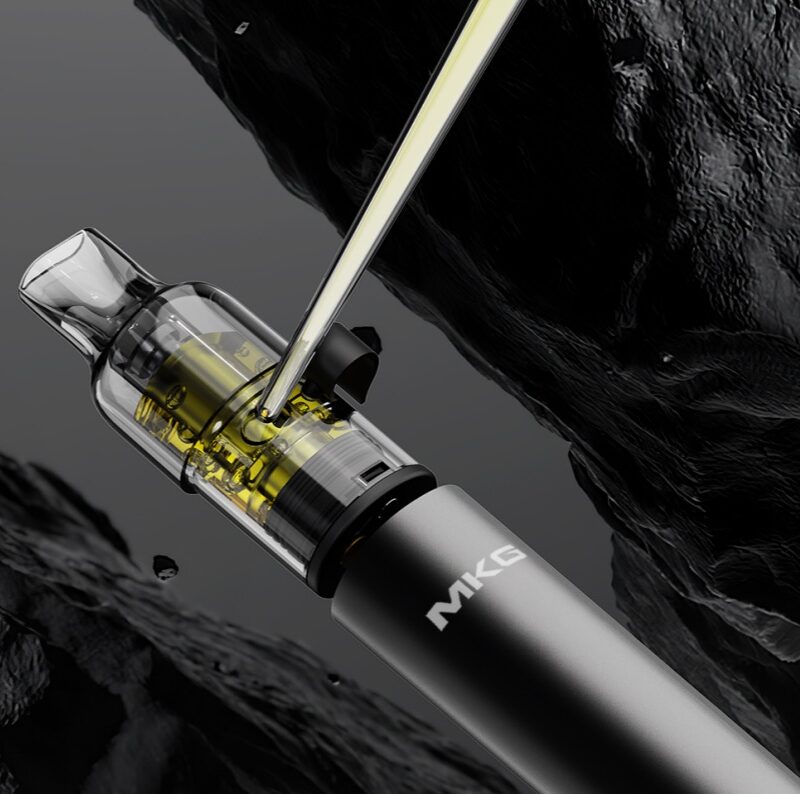

So far, e-cigarettes have a lot of appearance processes to choose from, such as anodizing, two-color injection molding, spraying, stickers, UV printing, skinning, 3D glass, etc. In terms of appearance effects, there are frosted, hand-painted, polished , gradient colors, patterns, etc.

Among them, it is understood that the most common appearance effect is gradient color, and there are two main processes used in gradient color that are relatively stable: anodizing and spraying.

1. Anodizing

Anodizing is the formation of an oxide film on the metal surface. Pure anodizing only includes the process of generating an anodized film.

If you need to color the metal, you need to dye and seal the holes to achieve the coloring effect.

Gradient color is achieved by regulating the dyeing time in the dyeing pool. The dye enters the molecular gap of the oxide film during the dyeing process. The longer the dyeing time, the more dye enters and the darker the color becomes. By controlling the time that the parts to be dyed stay in the dye through a computer, such as gradually pulling the workpiece away from the dye, a uniform gradient color effect can be achieved.

2. Spraying

Spraying is a processing method that uses a spray gun to atomize paint and apply it to the surface of an object. Coatings with wear resistance, corrosion resistance, heat insulation, conductivity, insulation, sealing, lubrication and other special mechanical physical and chemical properties can be obtained on various substrates. It has a very wide range of applications and is a traditional craft.

Gradient color spraying is a spraying equipment that uses more than two colors of paint. By modifying the equipment structure, one color can slowly transition to another color to form a new decorative effect. The equipment operation is relatively simple and efficient. It can be realized by simple gradient color spraying, which is easy for mass production and has high yield rate.

Of course, there are many processes that can achieve gradient colors, such as PVD coating, UV transfer, silk screen printing, color printing, etc. However, from the perspective of mass production difficulty, product yield, etc., electronic cigarette gradients can be achieved through anodizing/spraying. The color appearance is more cost-effective.

Electronic atomization and HNB products are both new electronic products. Although their structures are small, they incorporate a variety of materials, surface treatments, chip electronics and other technologies, and atomization technology is constantly changing.