The Puff Sensor is the mainstream startup sensor currently used in electronic cigarettes. The ability of electronic cigarettes to simulate the traditional smoking process is inseparable from the Puff Sensor.

When it comes to electronic cigarette Puff Sensor, the most common combination is a capacitive electret microphone + chip, which is installed on the solution board and connected to the heating wire and battery through lines to provide intelligent start, charge and discharge management, status indication, and output power. Management and other functions.

The working principle of the Puff Sensor: When smoking an electronic cigarette, the film inside the electronic cigarette microphone deforms and triggers the circuit switch to activate.

When suction stops, the membrane returns to its original shape and the circuit remains closed.

The Puff Sensor has many functions, which can be roughly summarized as follows:

1. Short circuit protection

2. Low battery protection

3. Timeout protection

4. Overcharge protection

5. Overcurrent/overtemperature protection

6. Power display

7. Low resistance protection

8. Control output

Its function mainly relies on the chip in the Puff Sensor. Puff Sensor are generally divided into two types, one is the condenser Mic (empty Puff Sensor, inside

There is no chip MCU on the surface) and it must be soldered to the circuit board.

1. Capacitive electret Puff Sensor

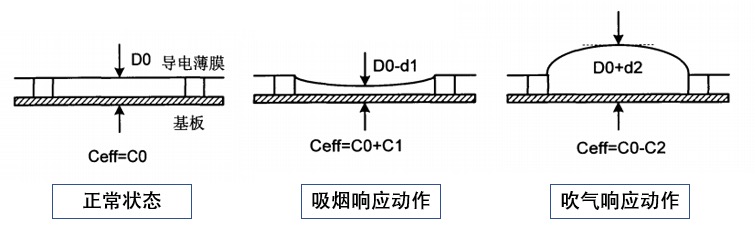

The principle of the capacitive Puff Sensor responding to external actions is that the air flow causes the deformation of the conductive film, thereby causing the equivalent capacitance to change. At the same time, in order to avoid external interference, when the change reaches a certain value, the detection module only outputs smoke to the internal Signal.

Capacitive Puff Sensor response action, derived from patent CN203353677U

Working principle: It can be derived from two formulas, C=εS/4πkd…① and C=Q/V…②.

As can be seen from the above figure, suction/blowing causes the conductive film to deform, changing the distance between it and the electrode plate, resulting in a change of Δd. Therefore, it can be seen from formula ① that a change of ΔC is bound to occur. According to the formula ② It is also known that due to the change of ΔC, the charging charge is fixed, so a change of ΔV is bound to occur.

This generates an electrical signal, which is then transformed and amplified through impedance, ultimately triggering the electronic cigarette to work.

2. Puff Sensor chip

After the capacitive Puff Sensor senses the start signal, the signal needs to be processed and fed back to the next step. At this time, it is the Puff Sensor chip’s turn to work.

Microphone chips are generally designed using ASIC, and the manufacturing process includes chip design, tape-out, packaging, testing and other links. It can integrate e-cigarette functions such as air flow sensor circuit, output power management, function control, charging management, status indication and protection circuit.

3. Working principle of Puff Sensor

The response of electret Puff Sensor and silicon Mic is to form a parallel plate capacitor through the diaphragm and the back plate. The differential pressure of the air flow causes the diaphragm to deform, and then the capacitance changes. After being identified and processed by the ASIC chip, an electrical signal is output. Finally, the electronic cigarette can be started and stopped.

The key point is the capacitance change.

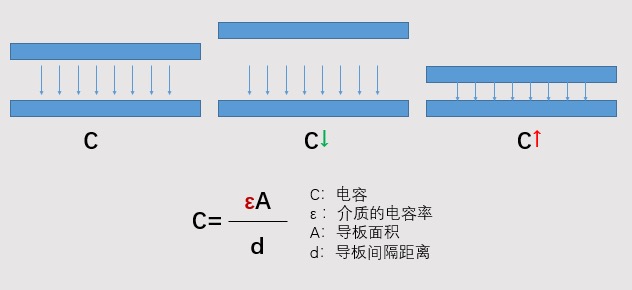

In circuit science, the ability of a capacitor to store charge at a given voltage is called capacitance, labeled C. The parallel plate capacitor is a simple capacitor consisting of two thin plate conductors parallel to each other and separated by space or dielectric.

According to the relevant formula of parallel plate capacitor, it is:

● Normal electronic cigarette Puff Sensor: The guide plate area A is fixed, the medium permittivity ε defaults to air, and the air flow deforms the diaphragm—the distance d between the diaphragm and the plate changes—causing capacitance changes;

● Oil leaking electronic cigarette Puff Sensor: The area A of the guide plate is fixed, and there is not air between the plate and the diaphragm, but e-cigarette oil. Then, the dielectric permittivity ε changes – causing a change in capacitance – self-starting.

4. Assembly and functional iteration of electronic cigarette microphones

The production process of electronic cigarette microphones is mainly assembly, sealing, patching, testing, welding, and inspection. Among them, the welding part was manual welding in the early days, and the consistency was difficult to guarantee. With the introduction and maturity of automated equipment, leading manufacturers now basically use automated welding.

In terms of types, the current electronic cigarette air flow sensor solutions include, in addition to microphones, MEMS differential pressure sensors, MEMS flow sensors, TPD barometers and other solutions.

In terms of functions, in order to meet the national standards and the requirements of some overseas countries and regions, child locks were once a hot spot in industry research and development. Problems such as self-starting, waterproofing and oil-proofing have also been solved one by one with the development and application of technologies such as nano-coating and new microphone structure design.